-

Recent Posts

Recent Comments

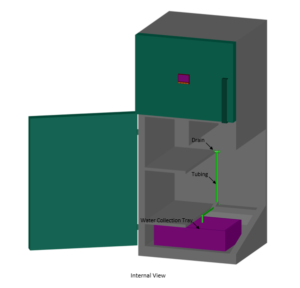

The Sustainable Fridge

The final product of ECE492 & ECE492.

Posted in Uncategorized

Leave a comment

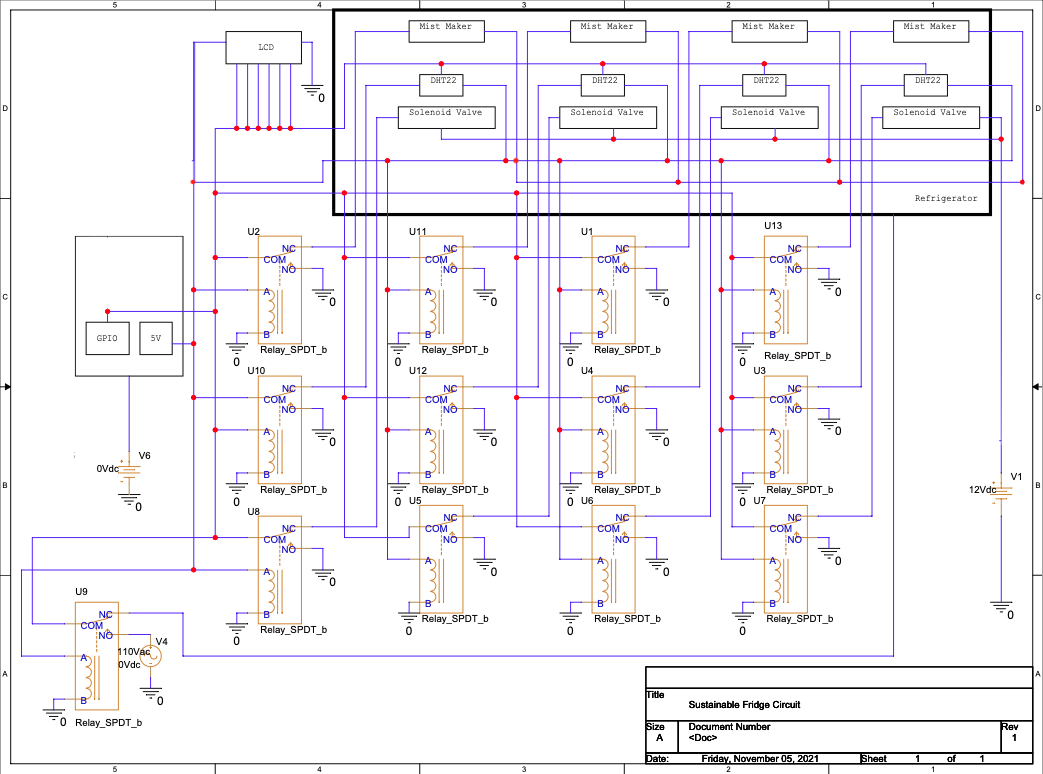

Final circuit diagram

The circuit used for the Sustainable Fridge.

Posted in Uncategorized

Leave a comment